Enhancing Safety: The Volt Stick SafeTouch Procedure for electrical hazard prevention

How safe is Your 'Safe to Touch' Procedure?

Every year, engineers and installers face life-threatening risks from stray electrical voltages on pipes, meters and metallic surfaces. Without a clear and accessible 'Safe to Touch' procedure, these dangers remain a silent threat.

But how safe is your current approach? And are you equipped with the right tools and knowledge to protect yourself and your customers?

The Hidden Danger: Stray Voltage in gas, plumbing and the wider installation industries

Gas field engineers and installers are at significant risk from stray electrical voltage on pipes, meters and metallic surfaces. This danger arises when an electrical system is grounded directly to a property's pipework. In the event of an electrical fault, the gas system and metallic surfaces can become live, creating a potentially fatal hazard for anyone working on or near them.

For example, an engineer servicing a gas meter or boiler could inadvertently come into contact with a live pipe, resulting in a severe or even fatal electric shock. This risk is not limited to gas engineers; plumbers, heating engineers and building services professionals also face similar dangers when working on metallic systems that may be inadvertently energised.

The need for a standardised 'Safe to Touch' Procedure

Ian Palmer, Operations Manager at Cert-ain Certification Ltd (CCL), explains: "Although some existing guidance refers to a 'Safe to Touch' procedure, there isn't a published procedure that is freely available to smaller companies and sole traders. This leaves many engineers without clear, actionable steps to ensure their safety."

leaves many engineers without clear, actionable steps to ensure their safety."

Ian Palmer has nearly 20 years of experience as a Technical Service Engineer with British Gas and now overseesa network of approved gas training and assessment centres across the UK. He identified a gap in the industry; while the Gas Safe Register mentions a 'Safe to Touch' procedure in Technical Bulletin TB118a, the details are limited and only accessible to Gas Safe registered engineers. This leaves trainees and the wider installer/engineer industry without clear guidance.

Recognising this gap, CCL enhanced its training programs with its own version of a 'Safe to Touch' procedure. However, the wider plumbing, heating and building services industries still lack a formalised approach, leaving many engineers vulnerable to electrical hazards.

Collaboration between CCL & Volt Stick: A proactive approach to safety

To address this critical issue, CCL reached out to Volt Stick, the inventors of the original Non-Contact Voltage Detector (NCVD). Volt Stick's LV50 device is already integral to the 'Safe to Touch' procedures of major companies like Cadent Gas, SGN and Wales & West. However, such comprehensive procedures were not readily available to smaller companies and sole traders.

Ian Palmer explains: "When it comes to safety, both CCL and Volt Stick believe we need to be proactive rather than reactive. By taking procedures already used by larger companies, adapting them and making them accessible to everyone, we can save lives."

"When it comes to safety, both CCL and Volt Stick believe we need to be proactive rather than reactive."

How Non-Contact Voltage Detectors (NCVDs) work

Non-Contact Voltage Detectors (NCVDs) are essential tools for identifying stray voltage without direct contact with the metallic surface. The Volt Stick LV50, for example, is a pen-sized device that detects the presence of AC voltage through capacitive coupling. When the device is held close to a live surface, an internal circuit is triggered, causing the device to light up and alert the user to the presence of a potentially lethal voltage.

Key Features of the Volt Stick LV50:

- Non-Contact Detection: Engineers can safely detect voltage without touching the surface, reducing the risk of electric shock.

- Quick and Easy to Use: The device provides instant feedback, allowing engineers to make rapid safety assessments.

- Portable and Durable: Its compact design makes it easy to carry, and it is built to withstand the rigors of fieldwork.

- Detects from the HSE's Safety Threshold of 50 volts.

- Is ATEX certified as intrinsically safe to use in hazardous areas.

Choosing the right Non-Contact Voltage Detector

Ian Palmer highlights a key issue: "We could not find any clear guidance on what to look for when choosing a non-contact voltage detector. The only advice available was to use an approved device."

To address this, CCL and Volt Stick have created the below flow chart to help engineers select the right NCVD for their 'Safe to Touch' procedure. Key considerations include:

- Sensitivity: The device should be capable of detecting low voltages from at 50 volts or below to ensure they meet HSE Regulations.

- Durability: Field engineers need devices that can withstand harsh working conditions.

- Ease of Use: The device should be intuitive and require minimal training to operate effectively.

- Intrinsically Safe: If the device is to be used in Hazardous Areas or where gas may be present then it should be ATEX or IECEx Approved.

(Information provided above is to be used as ‘Guidance Only’ and NOT as a written Safety Procedure)

A safer future for the industry

CCL and Volt Stick have reviewed existing procedures and guidance to create the Volt Stick SafeTouch Procedure. This initiative aims to provide clear, easy-to-follow guidance for the building services sector and other relevant industries. By equipping engineers and installers with the right tools and knowledge, the procedure reduces the risk of injury from electrical hazards and stray voltage.

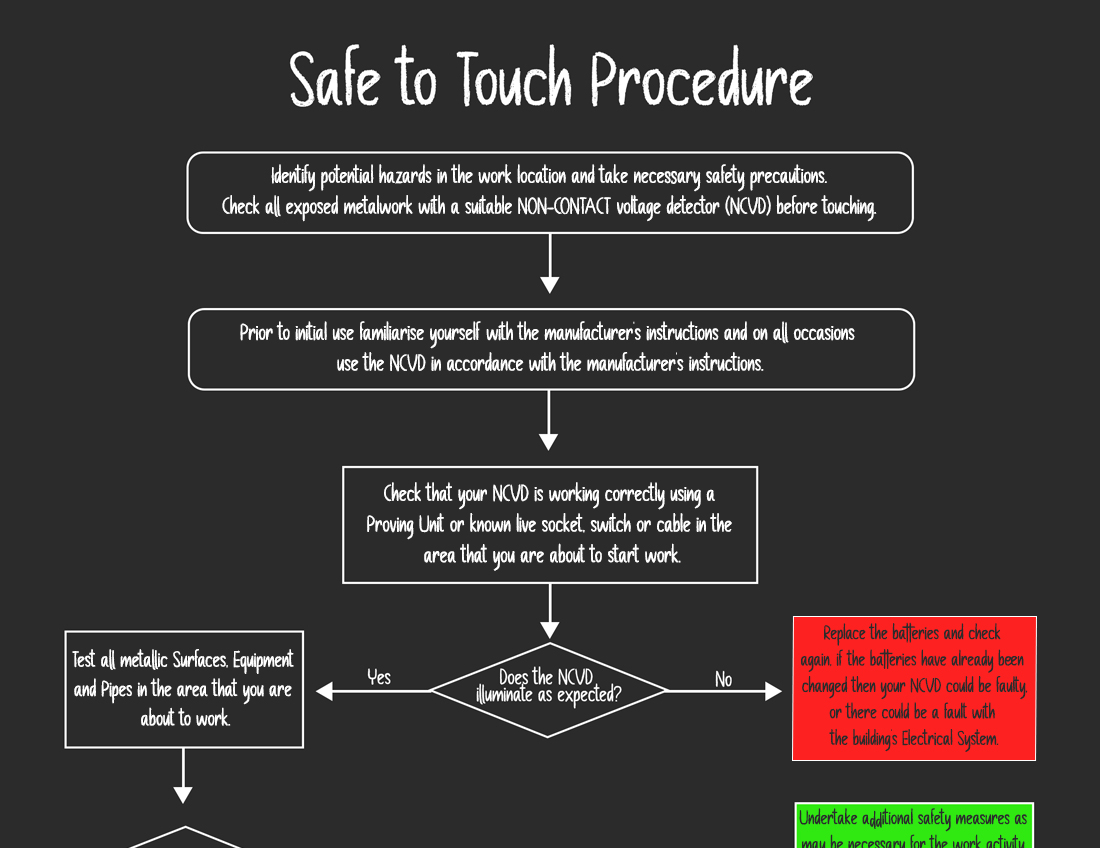

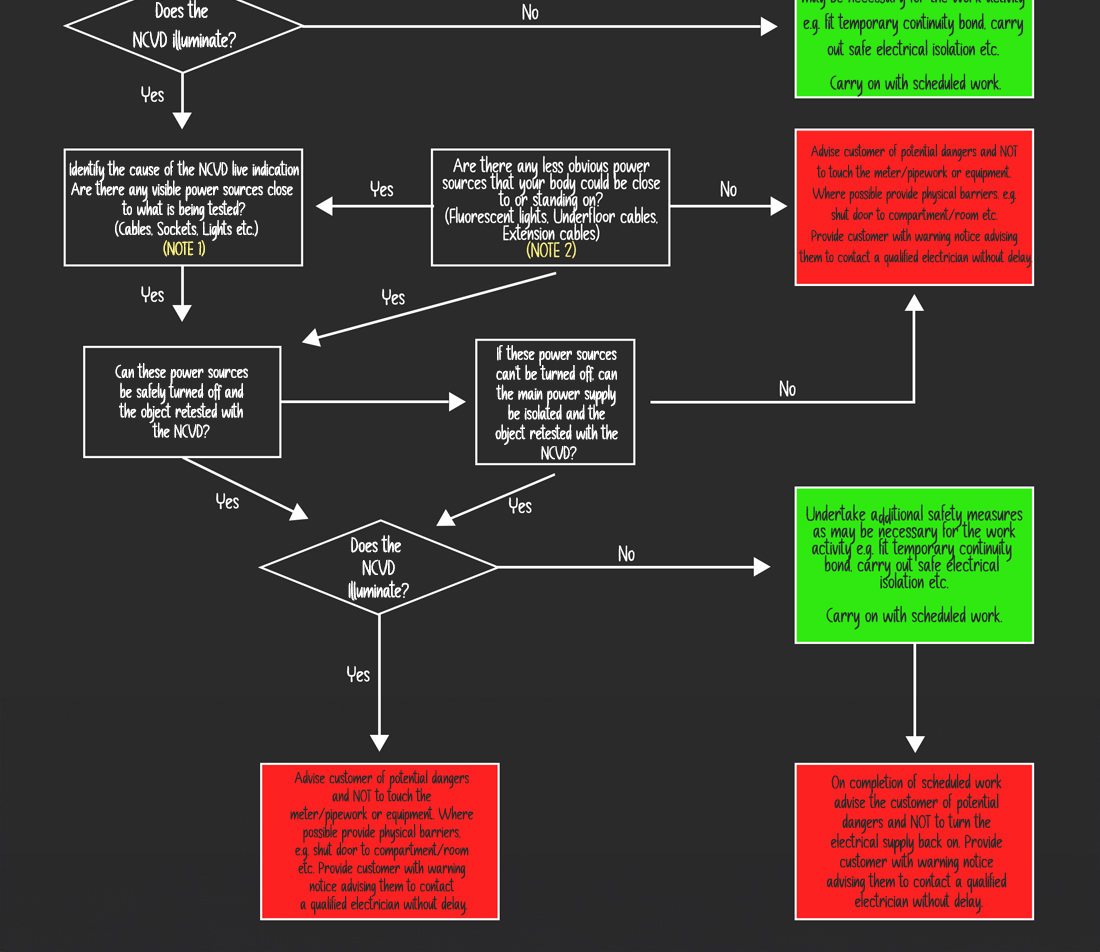

The Volt Stick SafeTouch Procedure: A Step-by-Step Guide

The collaboration between CCL and Volt Stick aims to develop a clear, practical 'Safe to Touch' procedure for engineers and installers. The goal is to make the process as safe, quick and easy to follow as possible, ensuring it is adhered to every time.

The below is an easy to follow procedure flow chart which gives guidance on how to use a NCVD to detect stray voltage on pipes and other metallic surfaces.

(Information provided above is to be used as ‘Guidance Only’ and NOT as a written Safety Procedure)

Safe to Touch Procedure - General guidance on the use of NON-CONTACT voltage indicators (NCVD)

Note 1. Induced Voltages – You must always assume that the object being tested is LIVE.

Nearby live sources can induce a voltage onto the object, such as extension leads or mains cables running close to pipes or metal casings. If it's safe, you should try turning off the power source to see if the live indication stops on the object being tested. If the indication stops, you have identified the source; if it continues, there is another cause for the indication. It's crucial to remember to always assume that the object is Live until you can identify and safely address the source of the live indication.

Note 2. Capacitive Coupling – Again, you must always assume that the object being tested is LIVE.

NCVDs operate on the principle of capacitive coupling, whereby they detect and indicate the electric field on the object being tested by completing a non-contact capacitive circuit to earth via the operator’s body. Interestingly, this process works in reverse as well; being near an electric field allows your body to capacitively couple with it, then, when you move the NCVD towards the object, it completes the capacitive circuit to earth, signalling the presence of a live voltage.

An example of this is, if you were to stand on or next to an electric cable, and, then move the NCVD towards a metal radiator connected to earth, then the NCVD would illuminate as you moved it towards the radiator. It would appear, that the radiator is live, but the NCVD is indicating the Voltage in the cable that your body is capacitively coupled with.

This means that the Volt Stick can detect live voltage even when the source is hidden or not immediately apparent.

Conclusion: Don’t leave safety to chance

Electrical hazards are a silent but deadly risk in the gas, plumbing, and building services industries. The Volt Stick SafeTouch Procedure is a proactive step toward ensuring the safety of engineers and installers. By adopting this procedure, you can protect yourself, your team, and your customers from the dangers of stray voltage.

Take action today: Equip yourself with the right tools and knowledge. Download the Volt Stick SafeTouch Procedure and make safety a priority on every job.

Key Takeaways

- Stray voltage on gas pipes and metallic surfaces can be fatal.

- A standardised 'Safe to Touch' procedure is essential for all engineers and installers.

- Non-Contact Voltage Detectors (NCVDs) provide the safest and quickest way to detect stray voltage.

- CCL and Volt Stick are working together to make safety procedures accessible to everyone.

.jpg)